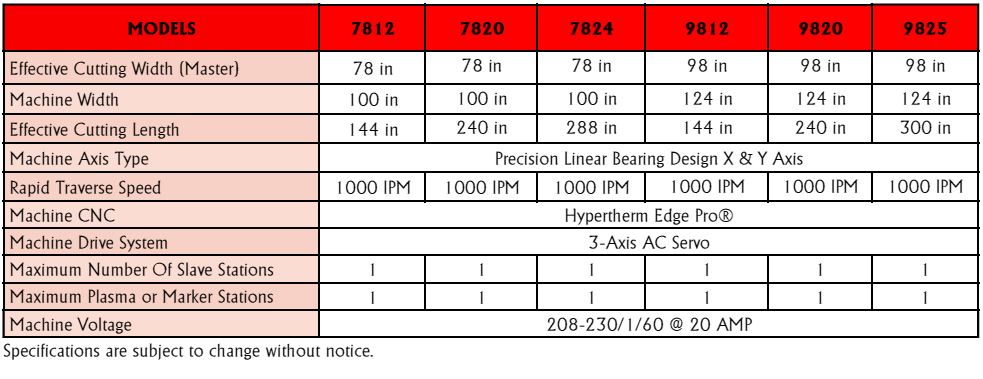

Supergraph IV

The Supergraph IV cutting system will boost your shop’s productivity and consistency, while reducing material waste by as much as 30%. With a traverse speed of up to 1000 inches per minute, you have the ability to maximize production without the loss of floor space. The compact design of the Supergraph IV also enables it to be easily moved and set up at a different location. This is truly a high powered, compact KOIKE cnc plasma cutting machine.

The Supergraph IV is one of a KOIKE’s cnc plasma cutting machine able to cut

- mild steel

- armor plate

- stainless steel

- aluminum and more

This machine is packed with exciting features and benefits ready to increase efficiency, quality and your bottom-line profitability.

Standard Features

- CNC Controller: Hypertherm® EDGE-Pro Shape Cutting Motion Controller

- Unitized Zoned Downdraft Table Design with CNC Controlled Pneumatic Damper Control for Zone Operation:

The table is designed to hold up to 1-1/4″ plate with removable slat frame assembly and/or individual slat removal. - Tuck Rail Design: Protects linear bearings, cable carrier, cables and hoses from harsh environments.

Optional: Removable slag pans are available.

Plasma System & Options

- Hypertherm HyPerformance/HyDefinition Plasma Systems

HyPerformance Plasma cuts fine-feature parts with superior quality and consistency while eliminating cost of secondary operations. The quick disconnect torch makes changing consumables fast and easy. Long consumable life, dross free edges, minimum angularity and high system reliability maximize productive “arc-on-time”. HyPerformance Plasma combines fast cutting speeds, rapid process cycling, quick changeovers and high reliability to maximize productivity. 130 amp to 260 amp systems are available to meet your production demands. - Hypertherm Conventional LongLife Air and Oxygen Plasma Systems

Heavy-Duty production tools with cost reducing LongLife technology for dramatically longer consumable life and much lower operating costs. The quick disconnect torch makes hanging consumables fast and easy. Impressive cut speeds, consistent cut quality and exceptional consumable life gives this plasma system a reliable performance across a wide range of industrial applications. - True Hole™ Ready

TrueHole™ Technology founded by Hypertherm® produces a significantly better hole quality than what has been previously possible before using plasma.

This technology was developed for mild steel from gauge to 1″ (25 mm) and has been optimized from a 1:1 to a 2:1 diameter to thickness ratio. - Fume Extraction Unit

- CNC Air Conditioning Unit: Provides additional cooling – required for machines operating in temps above 120 degrees F (48 degrees C)

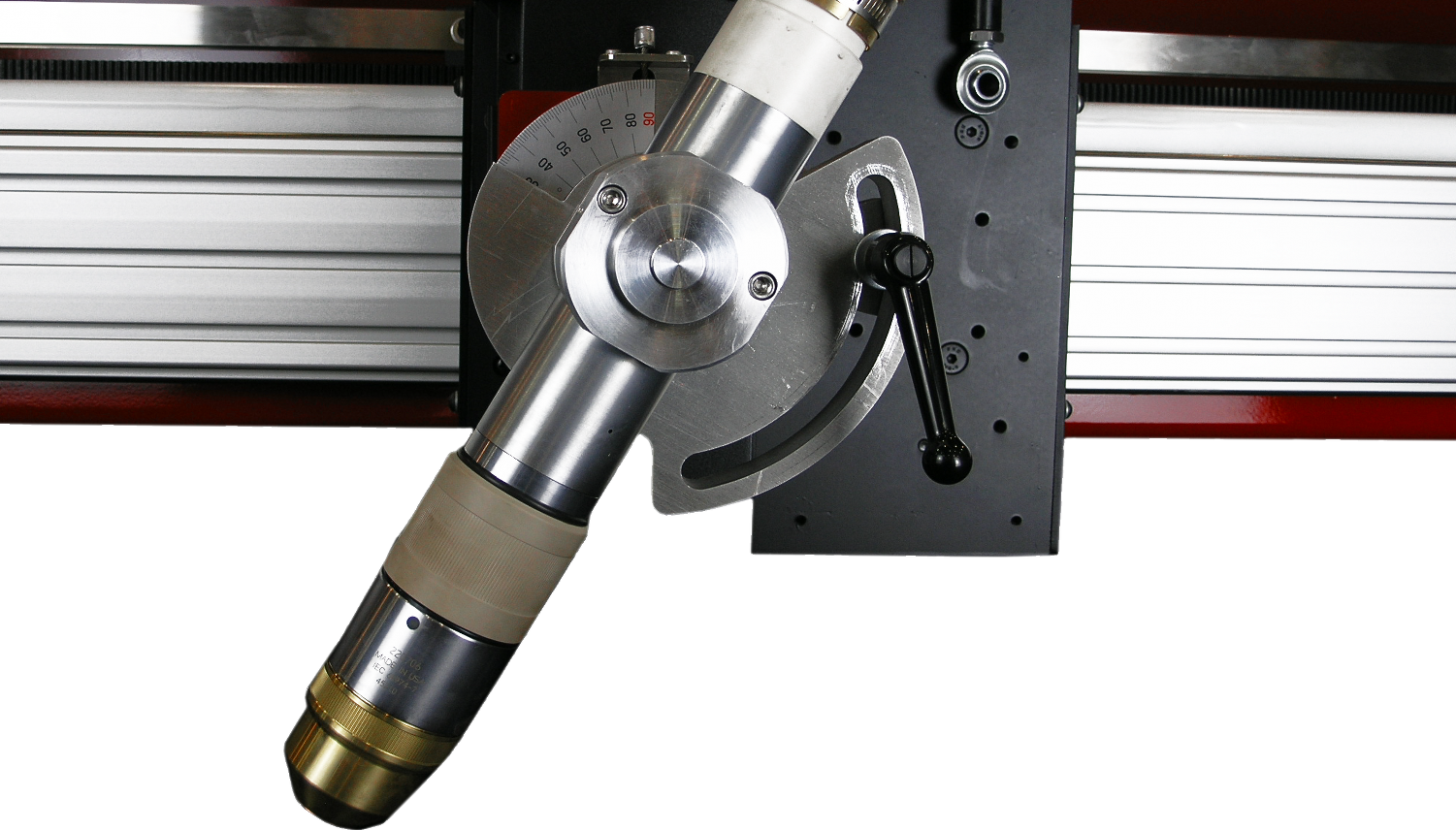

- Manual Plasma Bevel Station: Bevel in the rail axis only. Non-contour mechanical adjustment from +/- 0 – 45°.

- Hypertherm® ArcGlide Torch Height Control

Machine Components

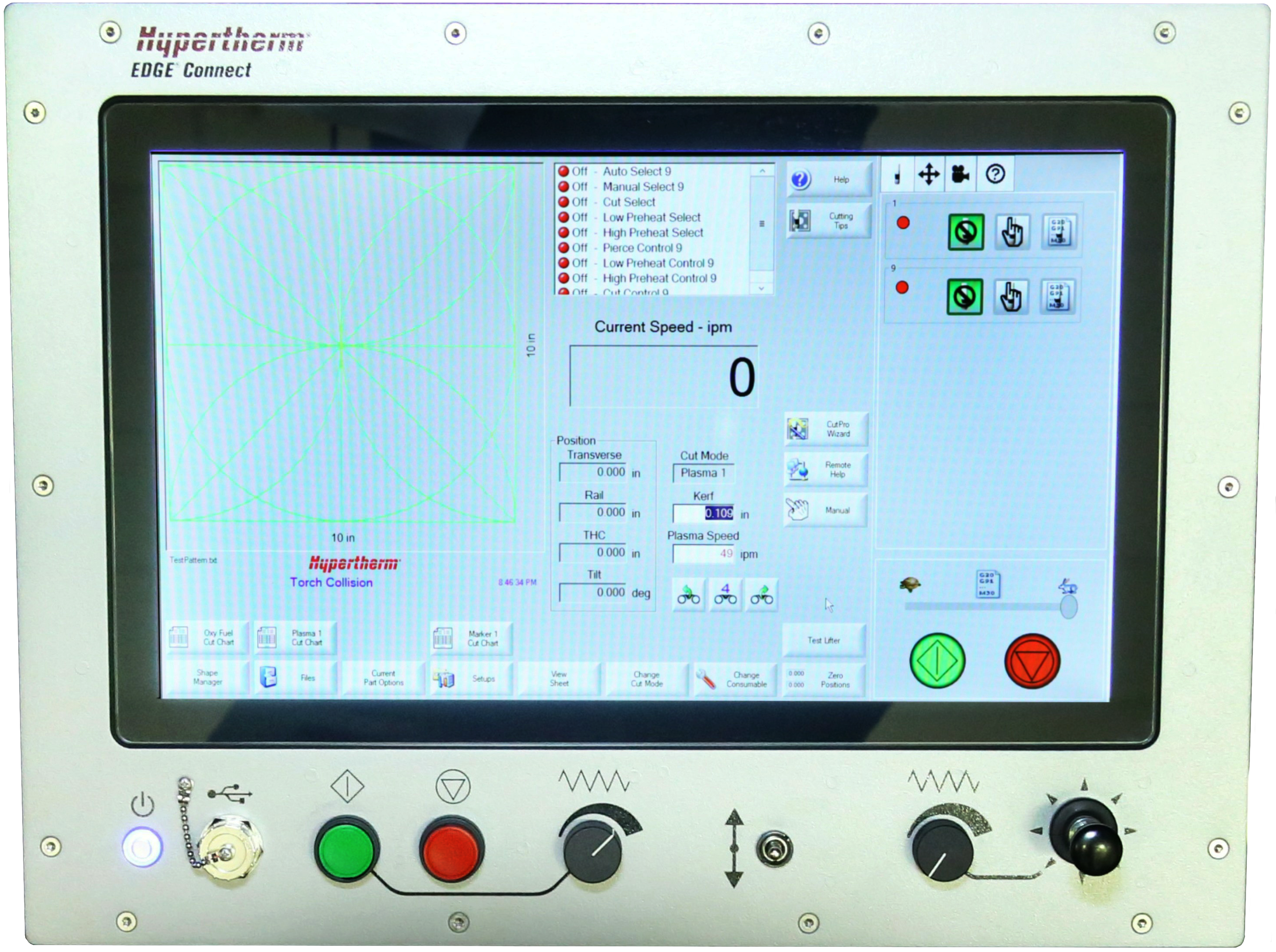

Hypertherm® EDGE CONNECT Features

Windows®10 Embedded

Intel J1900 Quad -core MCU or equivalent

120GB SSD Hard Drive or better

4 GB DDR3 or better

19 inch Glass Touchscreen with 1366×768 Native resolution

IntelliTouch Pro PCAP (Projected Capacitive touch technology)

2 USB 2.0 Ports

Built in Wireless Communication

Two Plasma Station Operator Console

Forward and backup on path function

Skip to pierce or Skip part function

Part Program Support

Remote Help

Supports Networking

Auto Gas Support

DXF Input

Simple Shape Nesting

Select-able Process Parameter table

Cut Pro Wizard

Pronest CNC version included (single part nesting)

Optional multiple part nesting available upon request

SureCut® technologies applied (True hole, Rapid Part and True Bevel when applicable)

Hypertherm HyPerformance/HyDefinition Plasma Systems

HyPerformance Plasma cuts fine-feature parts with superior quality and consistency while eliminating cost of secondary operations. The quick disconnect torch makes changing consumables fast and easy. Long consumable life, dross free edges, minimum angularity and high system reliability maximize productive “arc-on-time”. HyPerformance Plasma combines fast cutting speeds, rapid process cycling,quick changeovers and high reliability to maximize productivity. 130 amp to 260 amp systems are available to meet your production demands.

Hypertherm® Conventional LongLife Air and Oxygen Plasma Systems

Heavy-Duty production tools with cost reducing LongLife technology for dramatically longer consumable life and much lower operating costs. The quick disconnect torch makes changing consumables fast and easy. Impressive cut speeds, consistent cut quality and exceptional consumable life gives this plasma system a reliable performance across a wide range of industrial applications.

Conventional Plasma Systems offered for the Supergraph IV:

- Hypertherm® powermax65: has a production pierce of 1/2 inch mild steel

- Hypertherm® powermax85: has a production pierce of 5/8 inch mild steel

- Hypertherm® powermax105: has a production pierce of 3/4 inch mild steel

- Hypertherm® powermax125: has a production pierce of 1 inch mild steel

- Hypertherm® MAXPRO200: has a production pierce of 1 inch mild steel (Liquid Cooled Torch)

- Hypertherm® XPR300 with Optional Gas Console Boxes:

- Standard Core™console: Production Pierce 1.75 inch Mild Steel; 1.25 inch Stainless Steel

- Vented Water Injection: Production Pierce 2 inch Mild Steel; 1.5 inch Stainless Steel

- OptiMix console: Product Pierce 2 inch Mild Steel; 1.5 inch Stainless Steel

Plasma Cutting

Plasma cutting is a process of cutting electrically conductive metals, which utilize the electrically conductive gas to transfer energy from an electrical power source through a plasma cutting torch, thus melting the material. There are two types of plasma cutting processes:

Conventional Plasma Cutting

This process uses oxygen, air, and nitrogen for cutting. Conventional plasma cutting is a lower cost solution that will produce good quality cuts, but there will be some angle to the cut surface and the minimum hole quality is 3:1 to the plate thickness. Most conventional plasma systems run 65 amps, 85 amps, 100 amps and 200 amp systems. Mild steel cutting can be achieved from gauge material to 1-inch production pierce. Stainless steel and aluminum can be achieved from gauge material to 3/4-inch.

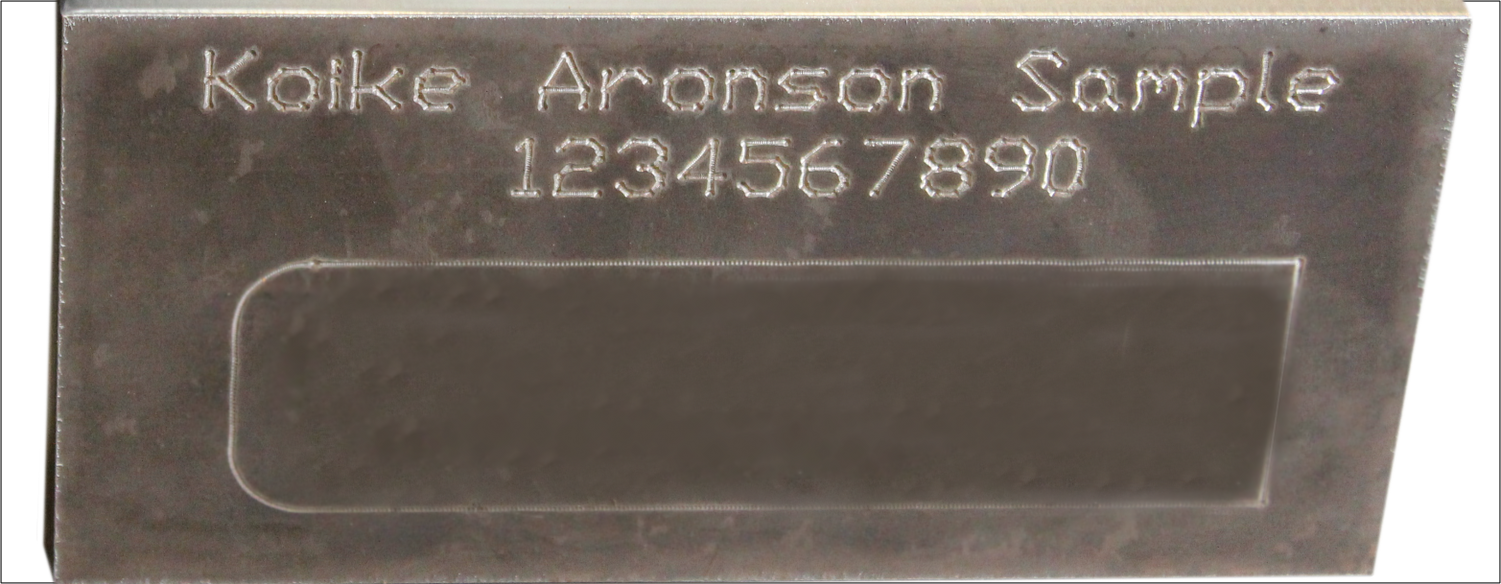

Hi-Definition Plasma Cutting

This process uses multiple gases for producing the highest quality parts. The hi-definition plasma uses the following gasses for cutting: oxygen, air, nitrogen, argon/hydrogen, and argon/nitrogen. If outfitted with an Auto Gas System, this plasma also has marking capabilities by using low amperage from the power supply. Argon gas is used for this marking process which is used to identify parts, bend lines, layout lines or drilling locations. This hi-definition plasma system will produce high quality cuts, and the angle to these parts is very minimal. Hole cutting quality on Mild Steel is a minimum of 1:1 ratio to the plate thickness up to a 1-inch plate. Quick change plasma torch heads make changing consumables fast and easy. Hi-definition plasma systems range from 130 amps, 260 amps, and 400 amps. Mild steel cutting can be achieved from gauge material to 2-inch production pierce. Stainless steel and aluminum cutting can be achieved from gauge material to 1-1/2 inches and with an 800 amp plasma system can production pierce up to 3-inches stainless steel.

Plasma Cutting Features

- Fastest Cutting Process

- Minimal Heat-Affected Zone

- Minimal Clean-Up

- Smooth Surface

- Cuts a Wide Range of Materials

Hypertherm® ArcGlide Torch Height Control

- 600 IPM Lifter Speed

- 9.4″ (240 mm) Lifter Travel

- Initial Height Positioning

- Corner AVC disable (prevents torch diving during corners)

- Extends consumable life by using

- Arc voltage sampling with automatic consumable wear adjustment

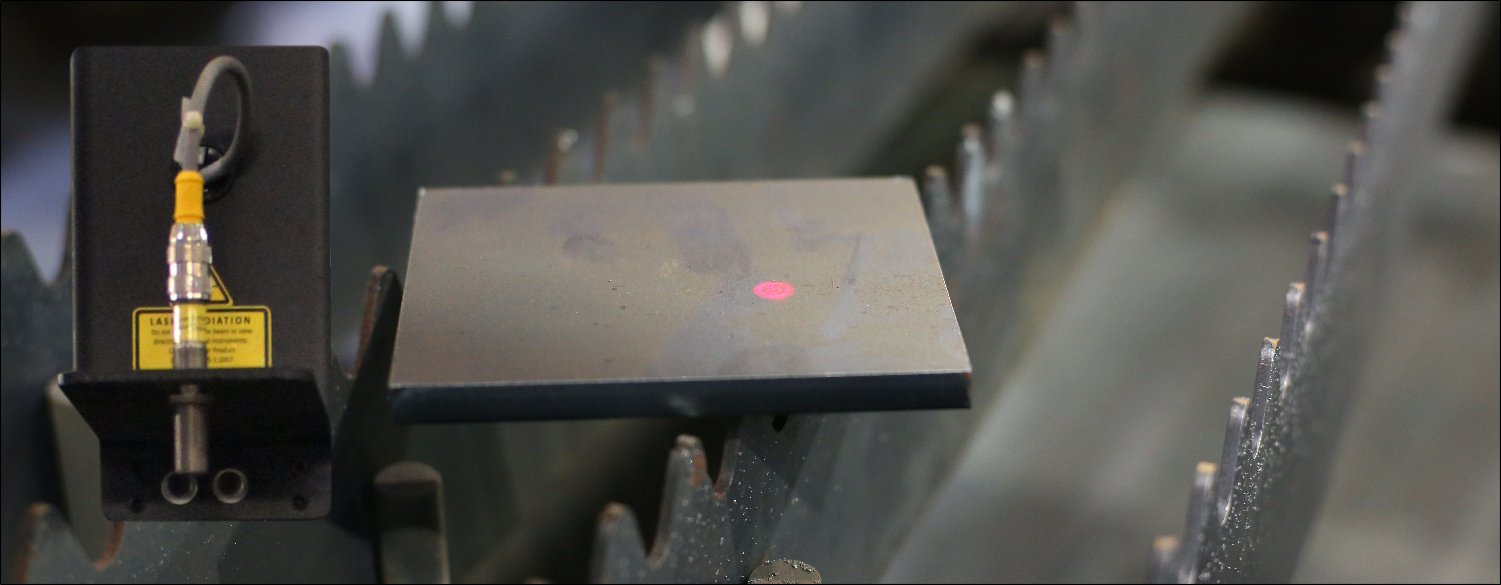

- Magnetic Torch Collision Detection: Integrated laser pointer with preset offsets

TrueHole™ Ready

TrueHole™ Technology founded by Hypertherm® produces a significantly better hole quality than what has been previously possible before using plasma. This technology was developed for mild steel from gauge to 1″(25 mm) and has been optimized from a 1:1 to a 2:1 diameter to thickness ratio.

Fume Extraction Unit | Donaldson Torit®

- Ledge-less construction

Eliminates dust build-up and accommodates wash down environments - Compact design

Minimizes floor space - Powerful performance

Proprietary ExtraLife™ Filter Cleaning System provides 30% more cleaning energy - Cost savings

Fewer filter change outs, reduced filter disposal costs, less energy usage - Reliability

Exceptional results for over 20 years and counting

Hypertherm CAM Solutions

ProNest LTS and LT Software

ProNest LTS (formerly known as NestMaster) is a CAD/CAM nesting software designed for light industrial, mechanized cutting in job shop environments. It provides a software solution for one cutting machine, equipped for either conventional plasma or oxy-fuel.

ProNest LT (formerly known as TurboNest) is a powerful CAD/CAM nesting software designed for light industrial, mechanized cutting in production environments. It provides a single software solution for all of your conventional plasma and oxy-fuel cutting machines.

SigmaNest Features

- TrueShape Nesting

- Wizard Based Prompts

- Remnant Teach Option

- Basic Geometry Edits

- Leverages Burny Advanced Plasma Interface by Embedding all Cut Chart Settings into the Part Program

- Adjust or Modify Lead-in / Lead-outs

- Automatic Path Generation

- Fill the Sheet with a Specific Part

Please consult factory about nesting software choices at 585-492-2400, ext. 430.

CNC Air Conditioning Unit

Provides additional cooling required for machines operating in temps above 120°F (49°C).

Consists of 1024BTU 115vac industrial tool grade air conditioner and CNC enclosure for external cooling of CNC cabinet.